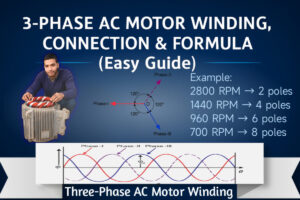

3 Powerful Coil Winding Digital Tools Every Rewinder Should Easy Use

What is Coil Winding Data Digital Tools?

Electrician, technician or motor-rewinder – winding work is fast only when the winding data is correct and accurate only when you have a good tool.

We will talk about 3 top coil winding data Digital tools, which every professional electrician, technician or motor-rewinder should have in their toolkit today:

tension-free and professional.

Motor Coil Winding Data Tools

Free To Use- Motor Coil Winding Data

Ceiling Fan Coil Winding Data Digital Tools

Free To Use Tool- Ceiling Fan Coil Winding Data

Table Fan Coil Winding Data Tools

Free To Use Tool- Table Fan Coil Winding Data

Purpose of Motor coil Windings.

- Copper coils in which current flows → magnetic field is formed

- This field interacts with stator–rotor to produce torque → shaft rotates.

- In AC motors stator windings produce RMF; in DC/BLDC/Stepper motors rotation is done by commutation/sequence.

- In single‑phase starting torque is obtained from start + run winding (capacitor).

- Winding design (turns, wire gauge, star/delta) decides voltage, torque, speed, efficiency and heating

Explore the Versatile Applications of Motor Coil Windings

Motor coil winding is a process in which an insulated wire (such as copper or aluminium) is lapped inside the motor to form a coil. This is how coil winding is done. When this coil is connected to the current, electromagnetism is created.Then it generates a magnetic field, which makes the motor rotate.

How does table fan coil winding work?

When current flows in the motor, a magnetic field is formed inside the winding. This magnetic field rotates the rotor, which makes the fan run. The running winding runs the motor continuously, and the starting winding helps in starting the motor.

Ceiling fan winding

Learn more about how coil windings contribute to everyday devices and enhance their performance in various applications.