Explore 6 powerful facts on Single Phase vs Three Phase motor winding. Know the benefits, differences, and expert tips to master electrical motor winding.

Single Phase vs Three Phase Winding – Full Difference in one article

What is motor winding and how does it work?

Basic Explanation

Single Phase vs Three Phase Winding

Motor winding is a process in which conductive wire (usually copper or sometimes aluminium) is wrapped (wound) around the inner-gird of the motor stator or rotor in such a way that when electric current flows through it, a magnetic field is created.

This magnetic field produces motion inside the motor, as the rotor rotates, the shaft of the motor keeps rotating.

The design and type of winding depends on – e.g.

AC Motor or DC Motor

Single Phase or Three Phase

When the motor winding is properly designed and installed, the motor rotates efficiently and smoothly.

What is Motor Coil Winding? Step-by-Step Guide & Process

What is single phase winding?

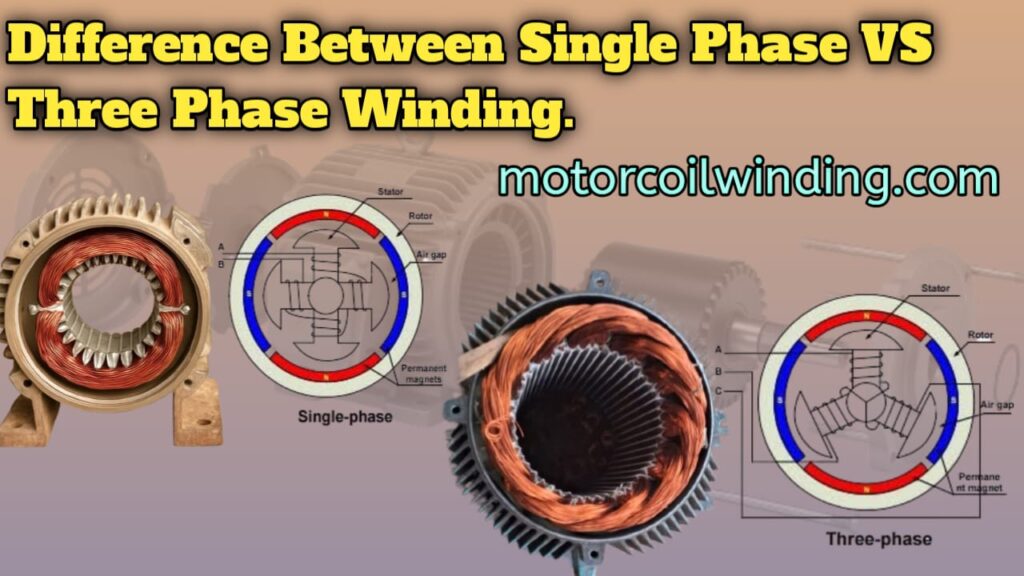

Single phase winding is a winding system that works with only one phase of alternating current (AC).

This means that the power supply is through only one line phase and one neutral. Voltage is usually 220V – 250V (in India).

How does it work?

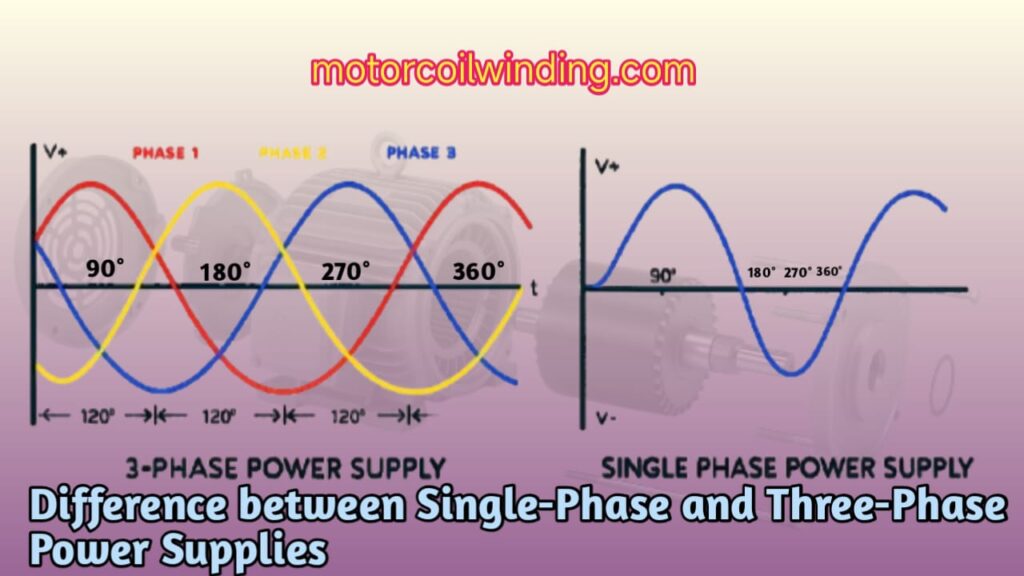

There is only one alternating current (AC) which changes its direction with time. This system has only one sinusoidal waveform which allows the current to flow in an alternate direction with time – first positive half cycle, then negative, and is also easy to use.

How is winding done?

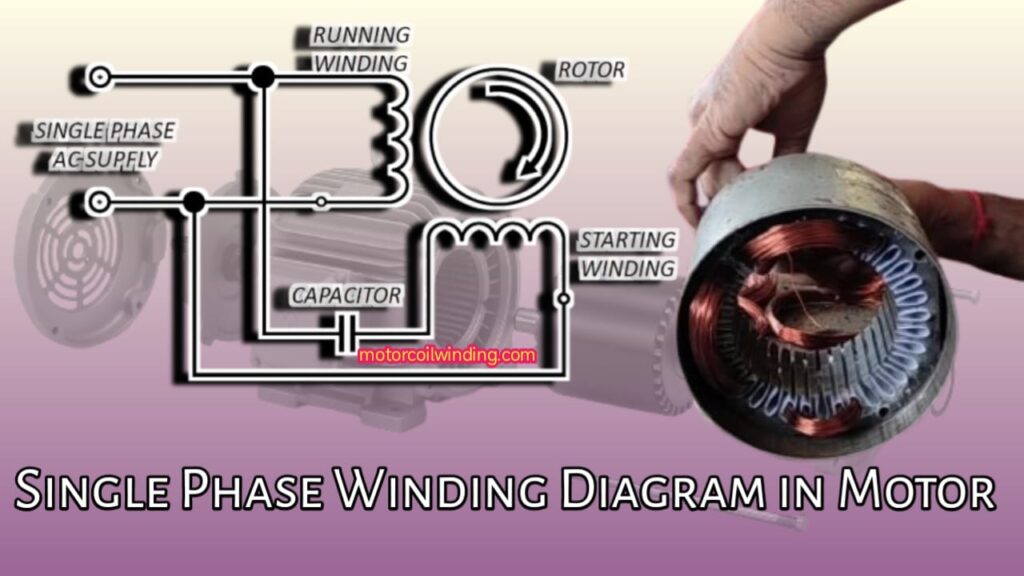

In a single phase motor there are two coil windings:

- Main winding (running winding)

- Starting winding (Auxiliary winding – which helps in starting the motor, like in capacitor start motor)

These coils are installed inside the stator, and when current passes through them a magnetic field is formed. But due to having only one phase, this magnetic field is alternating and pulsating (does not rotate), so the motor does not spin at the start.

To solve this problem, extra help is given in starting…

Capacitor

Auxiliary winding

Split phase technique

is used so that starting torque can be obtained.

How does it work? (Working)

When the switch is turned on:

Power enters the main winding

If there is a starting winding then the phase shift occurs with the capacitor

This phase difference creates a rotating magnetic field

The rotor starts rotating under the influence of this rotating field

As soon as the speed is achieved, the starting winding is cut off (through a centrifugal switch or relay)

Main Characteristics of Single Phase Winding:

| Feature | Details |

| Power Source | Single phase AC supply |

| Voltage | 220–230V standard |

| Connection | Wires 2 (Phase + Neutral) |

| Starting Torque | Low (without capacitor) |

| Speed Control | Difficult without controller |

| Vibration | More (due to torque pulsation) |

| Applications | Light duty motors, fans, AC units, etc. |

Where does it work? (Applications)

Single Phase vs Three Phase Motor- Single phase winding is used where:

- There is not much load

- Simple installation is required

- Cost effective system is required

- Power requirement is low or medium level

Real Examples:

- Home electrical devices

- Small motors,r

- Cooler, washing machine

- Geyser, TV, inverter

- Home ceiling fans

- Bathroom exhaust fans

- Refrigerators

- Small water pumps

- Domestic grinders

Types of Single Phase Motor Winding:

- Split Phase Winding – Basic starting winding system without capacitor

- Capacitor Start Motor – Capacitor is used in starting winding for high torque

- Capacitor Start Run Motor – One capacitor is used for both starting and running

- Shaded Pole Motor – Highly simple design, for small applications

Ceiling Fan Coil Winding 50+ Data Free PDF Includes Download

Construction

There are one or two coils wound on an iron core. When current passes through the coil, magnetic flux is generated.

What is three phase winding?

Basic Explanation:

Three phase winding is a winding system used in electrical machines — such as motors, alternators, transformers, factories, commercial AC systems, elevators, escalators, industrial pumps and compressors — in which three separate phases of AC current are used.

These three phases are named:

R (Red)

Y (Yellow)

B (Blue)

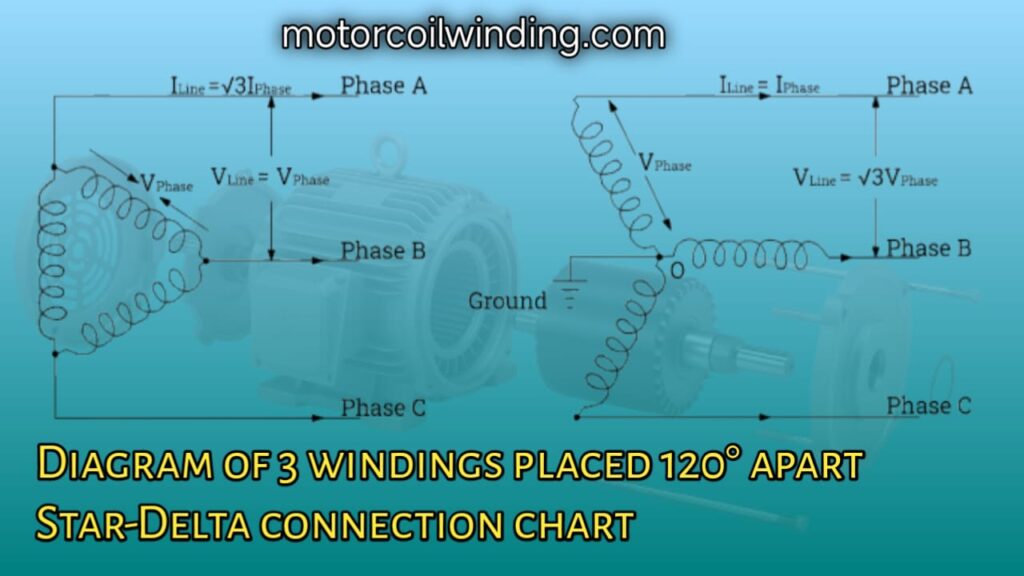

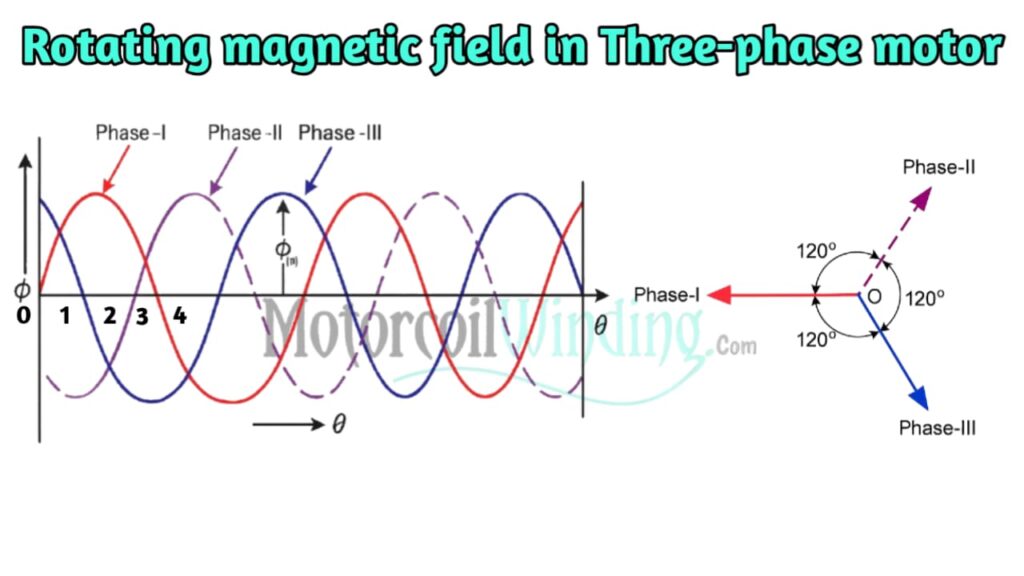

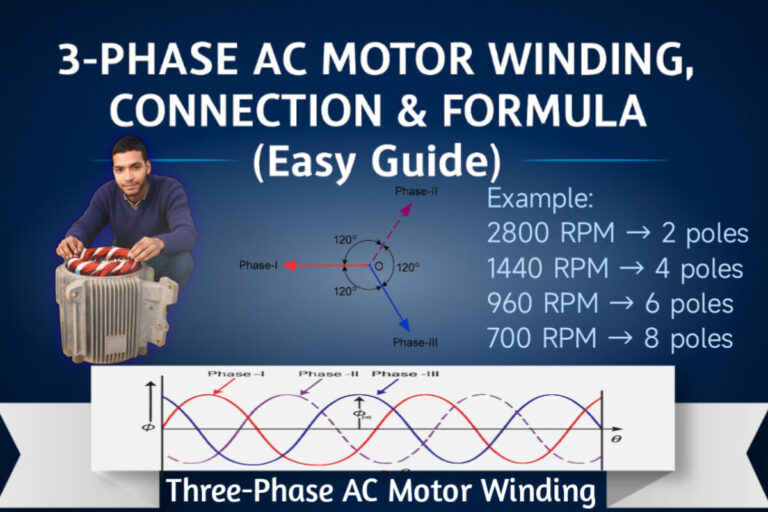

These three phases are at a gap of 120° angle, that is, the current in each winding flows with a slight delay, which creates a smooth rotating magnetic field. This keeps the system balanced and the power delivery is smooth, even under load.

Structure of Three Phase Winding:

- There are total 3 windings (coils) – installed on rotor or stator

- They are arranged in such a way that when current flows, a rotating magnetic field (RMF) is created

- This field revolves around the rotor, which makes the motor rotate

- There is no need for a starter, because it is self-starting

How does it work?

- As soon as three phase supply (R, Y, B) is applied, current starts in the three windings

- Because these three currents are 120° shifted, magnetism is generated in each winding with a little delay

- Result? A smooth and continuous rotating magnetic field

- This RMF attracts the rotor and the motor rotates smoothly

- Output torque is uniform, hence there is no vibration

Main Characteristics of Three Phase Winding:

| Feature | Details |

| No. of Phases | 3 (R, Y, B) |

| Phase Angle | 120° apart |

| Voltage | 400-440V (line voltage) |

| Power Supply Lines | 3 (or 4 with neutral) |

| Starting Torque | High |

| Efficiency | Very High |

| Rotation | Self-starting |

| Field | Rotating Magnetic Field (RMF) |

Types of connections:

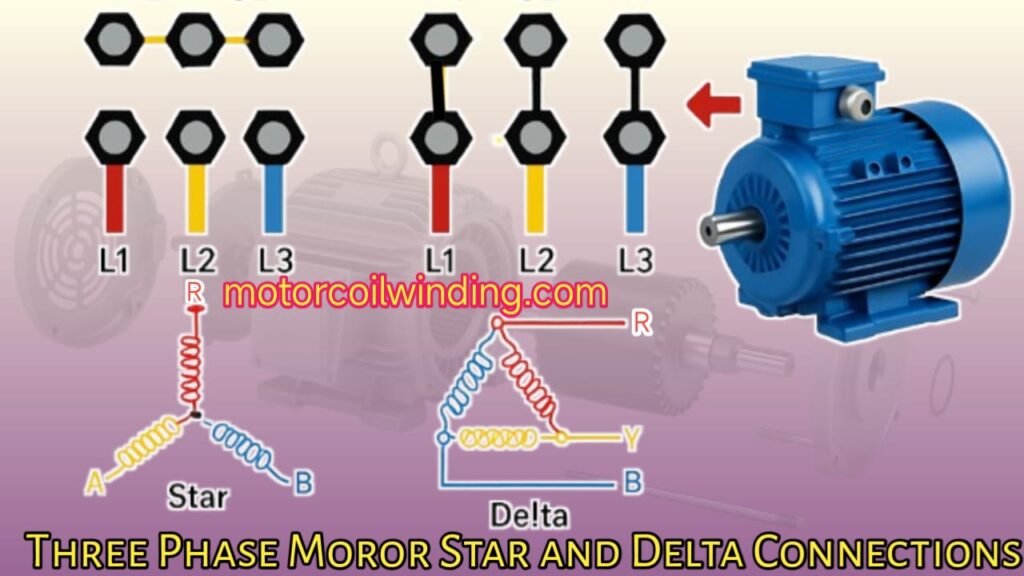

Three Phase Windings are connected in two ways:

- Delta Connection (Δ) – All windings form a closed triangle

- Star Connection (Y) – One end of all three windings meet at a common neutral point

What is the advantage of Three Phase Winding?

✅ Pros:

- Self-starting – no need of starter

- Smooth and ripple-free power

- Generates more torque

- Heat generation is less

- Long distance transmission possible with less losses

- Heavy load can be carried easily

❌ Cons:

- Wiring layout is complex

- Installation cost is more

- Skilled technician is required

- Cannot be used in single phase area

Applications – Where is it used?

Three phase winding motors and transformers are designed for heavy-duty applications.

Industrial Uses:

- Manufacturing machines

- CNC machines

- Conveyer belts

- Compressors

- Heavy-duty pumps

- Oil refineries

- Elevators / lifts

Commercial Uses:

- Centralized air conditioner systems

- Commercial buildings power supply

- Chillers and blowers

Is it ever used at home?

- Not in the general setup of the house, but if a 3-phase meter is installed then it can be used for appliances like high-end AC systems, lifts, or submersible motors.

Single Phase vs Three Phase Winding – Fast Comparison:

| Feature | Single Phase | Three Phase |

| Power Flow | Pulsating | Continuous |

| Torque | fluctuates | Is a constant |

| Starting | Need external help | Self-starting |

| Voltage | 230V | 400–440V |

| Efficiency | Low | High |

| Use Case | Light duty | Heavy duty |

A simple example:

Imagine you have a 5 HP industrial motor. If you use single phase winding, the motor will either not run or it will overheat.

But if you use three phase winding, the motor will run smoothly and efficiently – without consuming too much current.

Conclusion of this section:

Single Phase vs Three Phase

Three phase winding is a high power and highly efficient system used for large-scale applications.

The main objective of this winding system is continuous and consistent power delivery with less vibration and low heat.

If you need to run an industrial motor, compressor, or high-load machine, three phase winding is the best option.

Installation & Bill Cost – Which is Expensive or Cheap? Single Phase vs Three Phase

| Point | Single Phase | Three Phase |

| Setup Cost | Less | More |

| Meter | 1-phase meter | 3-phase meter |

| Monthly Bill | A little more | Work on heavy load |

| Wiring | Simple | Complex |

| Maintenance | Easy | Trined person required |

Single Phase vs Three Phase, Technical Working & Formula Comparison

Power Formula – Single Phase:

V = Voltage (Volts)

I = Current (Amperes)

cos(ϕ) = Power factor (lagging/leading)

- This formula shows how power is calculated on just one line in single phase. If the load is inductive (fan, motor), then the power factor is less than 1, which causes a difference between real power and apparent power.

Power Formula – Three Phase:

Power (P) = √3 × V × I × cos(ϕ)

√3 ≈ 1.732 (Constant for 3-phase systems)

V = Line voltage (Volts)

I = Line current (Amperes)

cos(ϕ) = Power factor

👉 From this formula it is clear that power delivery is more in 3-phase winding, even if current and voltage are equal to single phase.

Single Phase vs Three Phase – Technical Comparison

| Parameter | Single Phase | Three Phase |

| Number of Phases | 1 | 3 |

| Power Formula | V × I × cos(ϕ) | √3 × V × I × cos(ϕ) |

| Power Output | Less | More |

| Magnetic Field | Pulsating | Rotating |

| Starting | Capacitor | Self-starting |

| Torque | Fluctuating | Constant |

| Efficiency | Less | High |

| Power Factor Impact | There is more | lessens |

| Applications | Light load | Heavy load |

Example Calculation from Real Application:

Single Phase vs Three Phase Winding- Example: Single-Phase

A washing machine motor running on 230V and drawing 4A current, with power factor 0.8:

Power = V × I × cos(ϕ)

= 230 × 4 × 0.8 = 736 Watts

Single Phase vs Three Phase Winding- Example: Three-Phase

The factory pump is running at 400V, drawing 10A current, power factor is 0.9:

Power = √3 × V × I × cos(ϕ)

= 1.732 × 400 × 10 × 0.9 = 6,235 Watts

Conclusion:

Even with the same current and similar voltage, 3-phase winding is delivering more power – that is why 3-phase systems are mandatory in factories.

Power Factors & Losses

In single phase systems, there is a high chance of load fluctuations and power factor being low

In three phase systems, current flow is balanced => losses are low

Neutral wire is mostly used in single phase, it is not required in 3-phase balanced load.

Summary of This Section:

- Single phase winding passes current through one AC waveform, which gives pulsating torque

- Three phase winding has 3 AC waveforms at 120°, which create a rotating magnetic field

- Power formula uses a factor of √3 in three phases

- This is why three phase systems are more efficient, have higher torque, and are power saving

FAQs (Frequently Asked Questions)

Q1. Can I run a three phase motor with single phase?

- Answer:

Possible, but capacitor or phase converter will be required. Performance will not be perfect.

Q2. What is the advantage of three phase winding?

- Answer:

Constant torque, high performance, and voltage drop is less on long cable runs.

Q3. Which is best for home?

- Answer:

230V single phase system is best for home. It is cheap and easy to setup.

Q4. Which wiring is used for heavy machines?

- Answer:

Three phase winding, because it can easily bear more load.

Q5. What is single phase winding?

- Answer:

Single phase winding is a winding system which works on a single phase (alternating current). It is mainly used in small electrical devices of the house like fans, pumps, washing machines. It has low starting torque and starts with the help of a capacitor.

Q6. What is three phase winding?

- Answer:

Three phase winding is a winding system in which 3 separate phases of current (R, Y, B) are used, which are aligned at a phase angle of 120-degree. Its magnetic field rotates, hence these systems are self-starting and are best for heavy-duty applications.

Q7. Which is more efficient – single phase or three phase?

- Answer:

Three phase winding is more efficient. It has smooth torque, less vibration and better power handling capacity. Single phase system is simple and cheap, but efficiency is less than three phase.

Q8. Can a single phase motor be started without a capacitor?

- Answer:

Usually no. Single phase motor is not self-starting, hence a capacitor is installed along with the starting winding to get initial torque. Without capacitor the motor will not start or you will have to give manual push.

Q9. Can a three phase motor run on single phase power?

- Answer:

Yes, by using some special methods like capacitor bank, phase converter, or Variable Frequency Drive (VFD) a three phase motor can be run on single phase — but performance and efficiency will be low, and the motor can also heat up.

Q10. What is the voltage difference between single and three phase winding?

- Answer:

In India:

Single phase voltage ≈ 230V

Three phase voltage ≈ 400V to 440V

Three phase system has higher voltage, due to which more load can be carried.

Q11. Is three phase winding only meant for industries?

- Answer:

Mostly yes. But in some big houses or commercial buildings where there is more power requirement (like lift, big AC units), three phase is used there too – but in regular resident houses a single phase system is sufficient.

2 thoughts on “Single Phase vs Three Phase _6 Amazing Motor Winding Facts”

Pingback: 12 Table Fan Coil Winding Data –Full Guide with PDF Download

Pingback: 3-Phase AC Motor Winding, Connection & Formula (Easy Guide)