Manual Motor Coil Winding Machine Price in India

How much is the price of manual motor coil winding machine in India? If you work in a small workshop, motor rewinding shop, scooter/fan motor repair, transformer or hobby electronics, then manual coil winder is a budget-friendly and reliable choice. You will find in this detailed guide:

- Which type of machine is best for which work

- What features should you look for?

- Manual vs Semi-Auto vs Auto comparison

- Best deals (Amazon links with tag: motorcoilwind-21)

- FAQs, maintenance & safety tips

Quick Price Snapshot (In India)

Note: Prices fluctuate by brand, build quality, features, and location. Please check the product page for latest price.

| Category | Typical Use | Key Features | Approx. Price (₹) |

| Budget Manual | Hobby, small coils | Basic hand crank, 4-digit mechanical counter | 1,500 – 3,500 |

| Standard Manual | Small motor/transformer shops | Cast iron/MS body, bench clamp, 1:8–1:20 gear | 3,500 – 7,500 |

| Heavy-Duty Manual | Frequent/professional use | Larger chuck, smoother gear, sturdier bed | 7,500 – 15,000 |

| Pro Manual (with guide) | Precision layering | Traverse/guide rail, better tension control | 15,000 – 30,000+ |

| Hybrid Manual (motor-ready) | Future upgraders | Manual now, belt/motor attachable later | 12,000 – 25,000 |

What is Manual Motor Coil Winding Machine?

Manual Motor Coil Winding Machine is a hand-cranked machine that helps to wind the wire onto a coil in a controlled way. Common uses:

- Fan, pump ya scooter starter motor ki rewinding

- Small transformer/inductor coils

- Repair shops, polytechnic labs, DIY projects

Pros

- Low cost, low maintenance

- Portable, no need of electricity

- Full control over speed and turns

Cons

- Speed limited by manual effort

- Layering demands precision practice

- Time-consuming for heavy/stator windings

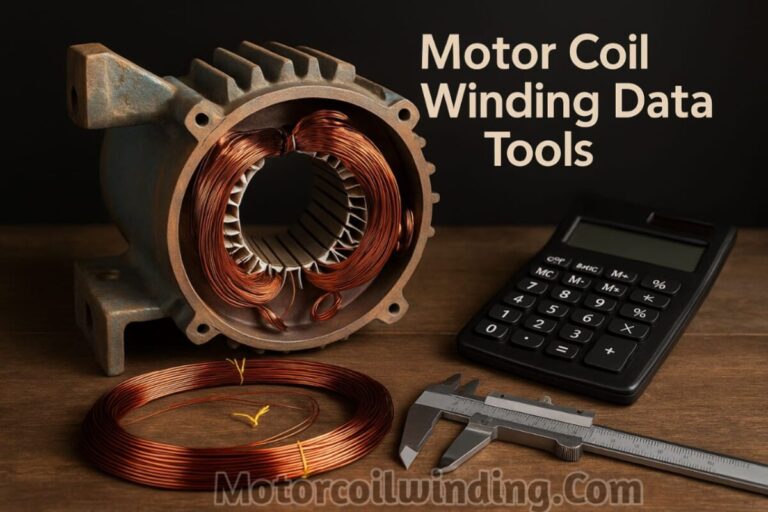

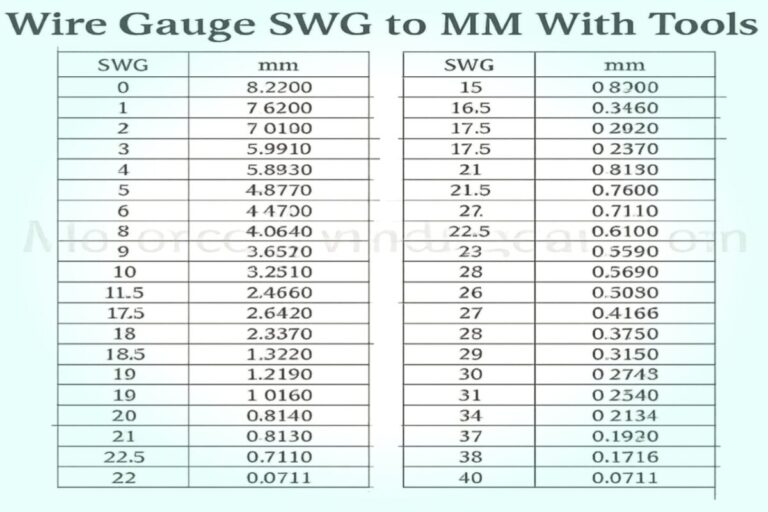

Wire Gauge Converter SWG to MM Best & No1 Conversion Tools

On what does the price depend?

Build Quality & Material

- Cast iron/MS body > more stable, heavy-duty

- Plastic/Light metal > budget, portable but less rigid

Counter Type

- Mechanical 4/5-digit counter: reliable & affordable

- Digital counter: better visibility, extra cost

Gear Ratio & Smoothness

- Higher gear ratios (1:20, 1:30) = smoother slow-speed control

- Backlash/jerks can occur in cheap gears

Chuck/Spindle & Capacity

- Adjustable chuck/mounts for different bobbin/armature sizes

- Wider bed = better support for larger coils

Traverse/Layer Guide

- Manual slide or leadscrew-based guide for neat layering

- Precision work me helpful (cost ↑)

Tension Control

- Basic felt/brake tensioner vs adjustable tension assembly

Warranty & Spares

- Local support, spare counters/gears availability

Manual vs Semi-Automatic vs Automatic

| Type | Control | Speed | Precision | Typical Price (₹) | Best For |

| Manual | Full manual | Low–Medium | Good (with practice) | 1.5k – 30k+ | Hobby, small shops |

| Semi-automatic | Motor + foot/knob control | Medium–High | Better repeatability | 15k – 80k+ | Busy repair shops |

| Automatic (CNC) | Programmed | High | Excellent | 80k – 5L+ | Production/industry |

Which Manual Motor Coil Winding Machine is best for you?

- Hobby/Student: Budget Manual with mechanical counter

- Small Repair Shop: Standard Manual (cast iron, bench clamp, good gear ratio)

- Frequent/Pro Use: Heavy-Duty Manual + traverse guide

- Future Upgrade Plan: Hybrid manual (motor-ready)

Top Picks & Best Deals (Amazon)

Note: Exact models keep changing. Check out the latest options on these searches:

- Budget Manual Coil Winder (with Counter)

- Link: https://amzn.to/45BARCz

- Typical Features: 0–9999 mechanical counter, hand crank, compact base

- Standard Cast Iron Manual Winding

- Link: https://amzn.to/4lQJob7

- Typical Features: Heavier body, steadier winding, better chuck support

- Manual Winding with Traverse/Layer Guide

- Link: https://amzn.to/4lyALBA

- Typical Features: Layering guide, smoother coil finish

- Hand Coil Winding for Small Coils/Transformers

- Link: https://amzn.to/47vSKFu

- Typical Features: Compact, quick setups for small bobbins

- Essential Accessories

- Coil Winder Counter (spare/upgrade): https://amzn.to/4mrdSBA

- Wire Tensioner: https://amzn.to/4luGxnO

- Enamelled Copper Wire: https://amzn.to/4oH8ZWe

- Soldering Station: https://amzn.to/47weot9

- Insulating Varnish: https://amzn.to/472h8OO

Tip: Prices drop a lot during Festival sales/Lightning Deals—keep track by making a wishlist.

Buying Checklist (Practical Points)

- Body & Base: Cast iron/MS stable? Bench clamp or base plate included?

- Counter: Mechanical is reliables? Reset smooth? Digit visible?

- Chuck & Mounts: Will they fit your bobbins/armatures?

- Gear Smoothness: Play/backlash is less. Knob rotation smooth.

- Spare Parts: Counter/handle/gears easily available?

- Warranty/Support: Please check Seller rating, return policy.

- Use Case Fit: Does your wire gauge range and coil size match?

How To Use (Basic Workflow)

- Prep

- Centre the bobbin/armature in the chuck and fix it.

- Place the wire spool on the stand and set the tension.

- Counter reset to 0.

- Trial Run

- Dry run for 10–20 seconds, adjust tension/guide.

- Winding

- Guide/tension from left hand, crank from right hand.

- It is important to keep the first layer tight and even.

- Keep watching counter on required turns.

- Layering

- Reverse direction per layer transitions me neat crossover.

- Paper/insulation between layers agar required.

- Finish

- Remove the leads and cut the wire.

- Tape/varnish as per spec, continuity test.

Safety Tips

- Avoid gloves (wire snag risk). Use eye protection.

- Do not wear loose sleeves/jewelry.

- Keep the speed slow in heavy coils.

- Keep away from children.

Maintenance Tips For Manual Motor Coil Winding Machine

- Counter: Dust-free maintenance, occasional light oil on allowed parts.

- Bearings/Spindle: Lubrication as per manufacturer guidance.

- Chuck: Jaws clean, light rust prevention oil.

- Tensioner pads: Clean, replace when glazed.

- Calibration: Counter slip/gear backlash notice before service.

Common mistakes (and their fixes) Manual Motor Coil Winding Machine

- Uneven Layers: Tension low or guide inconsistent. Fix: steady hand + traverse guide.

- Wire Breaks: Excessive tension or sharp edges. Fix: edges deburr, tension lower.

- Counter Mismatch: Slippage. Fix: pulley/belt align, set screw tighten.

- Coil Loose: First layer not tight. Fix: rewind from start, slow & steady.

Frequently Asked Questions (FAQs)

1) What is the price of manual motor coil winding machine in India?

- Budget: ₹1,499–3,499

- Standard: ₹3,499–7,499

- Heavy-duty: ₹7,499–14,999

- Pro manual (with guide): ₹14,999–29,999+

Latest deals: https://amzn.to/3Hh52ah

2) Can motor rewinding be done using manual winder?

Yes, it is possible for small motors (fan/pump/starter). For very large/heavy stators it will be time-consuming—semi-auto/auto better.

3) Is counter mechanical or digital better?

Mechanically reliable & budget-friendly. Digital visibility has improved. Both can be accurate, depending on quality.

4) Which wire gauge is supported?

Depends on machine specs. Typical manual winders for hobby/repair use handle fine wire (approx 18–36 SWG). Thick motor windings require heavy-duty chuck/tension. Always check product spec.

5) Is the traverse guide required?

Helpful for precision layering and neat finish, especially in transformers/inductors. Not so critical in motor stators.

6) Can we attach a motor to a manual machine?

Some hybrid models are motor-ready. Attaching a DIY motor may be unsafe—only if the manufacturer supports it.

7) Which are the best accessories?

Wire tensioner, spare counter belt, bobbin clamps, enamelled copper wire, insulating paper/varnish, continuity tester. Accessories: https://amzn.to/3JdTHZ9

8) How to check warranty and returns?

Check the warranty note, return window, and ratings/reviews on the seller page. Don’t forget to look at the “Return Policy” section when purchasing on Amazon.

9) Is manual Winding good for beginners?

Absolutely. The learning curve is small. You can start on a budget and later upgrade to semi-auto.

10) Where can I get it offline?

Local industrial tool markets, electrical rewind suppliers, and vocational lab suppliers. Also check online listings for price comparison.

Conclusion

If you are looking for a value-for-money solution, manual motor coil winding machine is the perfect entry point. Budget models are best for hobby/learning, standard/heavy-duty models are best for daily shop use. Price largely depends on build, counter, gear smoothness, and traverse guide. Check out these searches for the latest prices and best deals In India:

- Manual coil winding machines: https://amzn.to/4mnTqS1

- With counter: https://amzn.to/4mwuesk

- Cast iron builds: https://amzn.to/45UxIiv

Happy winding!

1 thought on “Manual Motor Coil Winding Machine No1 Best Deals in India”

Pingback: All in 1 Easy Motor Coil Winding Data Tools for Electrician