Detailed guide of Farrata fan and exhaust fan motor coil winding data. Aluminum and copper wire winding specifications, capacitor values, coil size, turns, coil pitch, and everything else explained in one article. PDF download also available.

Farrata Fan & Exhaust Fan Coil Winding Data – Full Details

Introduction:

Understanding motor coil winding data is very important for every technician, motor repairer, and manufacturer. In this article, we will provide you with 13 different ferrata fan and exhaust fan motor coil winding data points, which include specifications for both Aluminum and copper wire. This data will help you to increase the accuracy and efficiency of motor winding. You will also get a PDF download link of the complete data, which you can refer to offline as well.

Farata Fan Motor Winding Data – Aluminium & Copper Wire

Farata fan motors use both aluminium and copper wire. Aluminium wire is lighter and cost-effective, while copper wire provides more conductivity and durability. The winding specifications of both are slightly different, which we will explain in detail below.

5 Blade Farata Fan Coil Winding Data (Aluminium Wire) – Detailed Overview

This 5 blade Farata fan is made of aluminium wire, in which both the efficiency and durability of the motor have been kept in mind. It uses capacitor 4 MFD which provides smooth start and running torque to the motor.

All type Motor Coil Winding Data tool

- Stamping Size: 20mm to 1 inch (according to the size of the motor core)

- Inner Die: 60mm(space for coil inside the motor)

- Capacitor: 4 mfd (for motor start and run)

- Running Winding:

- Total Coil: 4 (for the running phase of the motor)

- SWG: 31 (wire thickness)

- Turns: 180 (wire ke rounds)

- Coil Size: 22 inch (wire ki total length)

- Coil Pitch: 1-4 = 1 Round,

- 1-6 = 2 Round (gap between turns of coil)

- Starting Winding:

- Total Coil: 4

- SWG: 31

- Turns: 180

- Coil Size: 21.5 inch

- Coil Pitch: 1-4 = 1 Round,

- 1-6 = 2 Round (gap between turns of coil)

This winding data optimises the performance of the motor, improving both the speed and durability of the fan.

5 Blade Farata Fan Winding Data (Aluminium Wire, SWG 30 & 32) – Slightly different specifications

In this model the wire thickness is slightly different (SWG 30 for running winding and SWG 32 for starting winding), which increases the current handling capacity of the motor. Capacitor value is same 4 mfd.

- Running Winding:

- Total Coil: 4

- SWG: 30

- Turns: 160

- Coil Size: 22 inch

- Coil Pitch: 1-4 = 1 Round, 1-6 = 2 Round

- Starting Winding:

- Total Coil: 4

- SWG: 32

- Turns: 170

- Coil Size: 21.5 inch

- Coil Pitch: 1-4 = 1 Round, 1-6 = 2 Round

This design gives a little more power and stability to the motor.

5 Blade Farata Fan Winding Data (Copper Wire) – High Conductivity

Due to copper wire the conductivity and heat resistance of the motor is better. In this model also capacitor 4 mfd is used.

- Running Winding:

- Total Coil: 4

- SWG: 31

- Turns: 160

- Coil Size: 22 inch

- Coil Pitch: 1-4 = 1 Round, 1-6 = 2 Round

- Starting Winding:

- Total Coil: 4

- SWG: 31

- Turns: 170

- Coil Size: 21.5 inch

- Coil Pitch: 1-4 = 1 Round, 1-6 = 2 Round

Copper wire improves both the life and performance of the winding motor.

5 Blade Farata Fan Winding Data (Copper Wire, SWG 33) – Heavy Duty

This winding uses a little thin wire (SWG 33) but has a lot of turns (200), which gives good torque and speed of the motor.

- Running Winding:

- Total Coil: 4

- SWG: 33

- Turns: 200

- Coil Size: 22 inch

- Coil Pitch: 1-4 = 1 Round, 1-6 = 2 Round

- Starting Winding:

- Total Coil: 4

- SWG: 33

- Turns: 200

- Coil Size: 21.5 inch

- Coil Pitch: 1-4 = 1 Round, 1-6 = 2 Round

This winding is suitable for higher RPM and power.

2 Blade Farata Fan Coil Winding Data (2800 RPM) – Aluminium & Copper Wire

Aluminium Wire Winding Data – High Speed Fan

2 blade fan whose RPM is 2800, made with aluminium wire. Capacitor is 3.15 mfd which gives fast start and smooth running to the motor.

- Running Winding:

- Total Coil: 2

- SWG: 32

- Turns: 240

- Coil Size: 30 inch

- Coil Pitch: 1-8 = 1 Round, 1-10 = 1 Round, 1-12 = 1 Round

- Starting Winding:

- Total Coil: 2

- SWG: 32

- Turns: 230

- Coil Size: 30 inch

- Coil Pitch: 1-8 = 1 Round, 1-10 = 1 Round, 1-12 = 1 Round

Copper Wire Winding Data – Durable & Efficient

2 blade fan winding with copper wire, which has slightly more turns (250 in running winding), which increases the efficiency and heat resistance of the motor.

- Running Winding:

- Total Coil: 2

- SWG: 33

- Turns: 250

- Coil Size: 30 inch

- Coil Pitch: 1-8 = 1 Round, 1-10 = 1 Round, 1-12 = 1 Round

- Starting Winding:

- Total Coil: 2

- SWG: 33

- Turns: 240

- Coil Size: 30 inch

- Coil Pitch: 1-8 = 1 Round, 1-10 = 1 Round, 1-12 = 1 Round

2 Blade Farata Fan (Copper Wire, Inner Dye 45 mm) – Compact Design

In this model the inner dye is 45mm, which makes the motor compact. The capacitor is 3.15mfd.

- Running Winding:

- Total Coil: 2

- SWG: 33

- Turns: 250

- Coil Size: 28 inch

- Coil Pitch: 1-8 = 1 Round, 1-10 = 1 Round, 1-12 = 1 Round

- Starting Winding:

- Total Coil: 2

- SWG: 33

- Turns: 250

- Coil Size: 27.5 inch

- Coil Pitch: 1-8 = 1 Round, 1-10 = 1 Round, 1-12 = 1 Round

2 Blade Farata Fan (Aluminium Wire, Inner Dye 45 mm)

Compact motor winding with aluminium wire, having capacitor 3.15 mfd.

- Running Winding:

- Total Coil: 2

- SWG: 32

- Turns: 230

- Coil Size: 28 inch

- Coil Pitch: 1-8 = 1 Round, 1-10 = 1 Round, 1-12 = 1 Round

- Starting Winding:

- Total Coil: 2

- SWG: 32

- Turns: 230

- Coil Size: 27.5 inch

- Coil Pitch: 1-8 = 1 Round, 1-10 = 1 Round, 1-12 = 1 Round

- Ceiling Fan Coil Winding 50+ Data Free PDF Includes Download

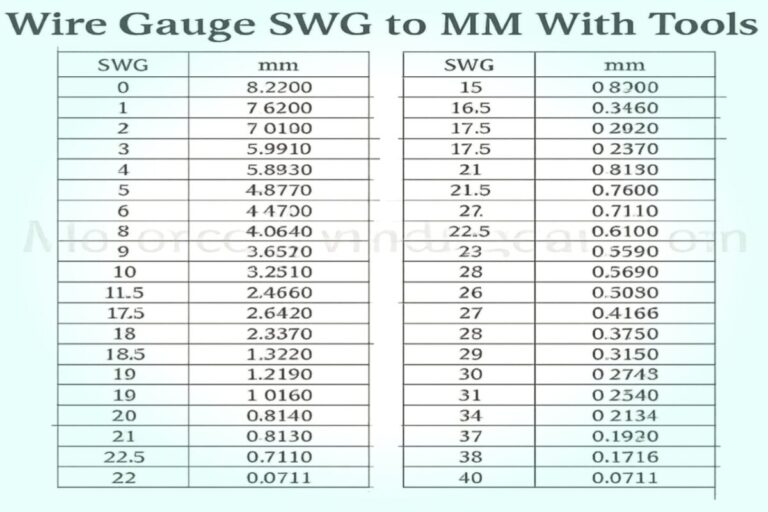

- Wire Gauge Converter SWG to MM Best & No1 Conversion Tools

- Buy Now pedestal fan

2 Blade 2800 RPM Farata Fan (Copper Wire, Inner Dye 45 mm)

- Running Winding:

- Total Coil: 2

- SWG: 33

- Turns: 230

- Coil Size: 28 inch

- Coil Pitch: 1-8 = 1 Round, 1-10 = 1 Round, 1-12 = 1 Round

- Starting Winding:

- Total Coil: 2

- Coil Size: 27.5 inch

- Coil Pitch: 1-8 = 1 Round, 1-10 = 1 Round, 1-12 = 1 Round

2 Blade Farata Fan (Copper Wire, Capacitor 2.5 mfd) – High Turns

The capacitor in this winding is 2.5 mfd and the turns are up to 300, which gives more torque and power to the motor.

- Running Winding:

- Total Coil: 2

- SWG: 35

- Turns: 300

- Coil Size: 28 inch

- Coil Pitch: 1-8 = 1 Round, 1-10 = 1 Round, 1-12 = 1 Round

- Starting Winding:

- Total Coil: 2

- Coil Size: 27.5 inch

- Coil Pitch: 1-8 = 1 Round, 1-10 = 1 Round, 1-12 = 1 Round

Exhaust Fan Motor Winding Data (3 Blade, 1440 RPM)

Aluminium Wire Winding Data – Standard Exhaust Fan

- Stamping Size: 20mm to 1 inch

- Inner Dye: 75 mm

- Capacitor: 5 mfd

- Running Winding:

- Total Coil: 4

- SWG: 26

- Turns: 120

- Coil Size: 23.5 inch

- Coil Pitch: 1-4 = 1 Round, 1-6 = 2 Round

- Starting Winding:

- Total Coil: 4

- SWG: 28

- Turns: 130

- Coil Size: 23 inch

- Coil Pitch: 1-4 = 1 Round, 1-6 = 2 Round

Aluminium Wire Winding Data (Slightly Different SWG & Turns)

- Running Winding:

- Total Coil: 4

- SWG: 28

- Turns: 140

- Coil Size: 23.5 inch

- Coil Pitch: 1-4 = 1 Round, 1-6 = 2 Round

- Starting Winding:

- Total Coil: 4

- SWG: 30

- Turns: 150

- Coil Size: 23 inch

- Coil Pitch: 1-4 = 1 Round, 1-6 = 2 Round

3 Blade Pendestal Fan Winding Data (Copper Wire, SWG 30 & 32) – Slightly different specifications

Copper wire is used for 3 blade Pendestal Fan, in which the running winding has a little more turns (250). This increases the efficiency of the motor and also improves the heat resistance, due to which the motor runs smoothly for a longer time.the current handling capacity of the motor. Capacitor value is same 4 mfd.

- Running Winding:

- Total Coil: 4

- SWG: 30

- Turns: 250

- Coil Size: 31 inch

- Coil Pitch: 1-4 = 1 Round, 1-6 = 2 Round

- Starting Winding:

- Total Coil: 4

- SWG: 32

- Turns: 210

- Coil Size: 30 inch

- Coil Pitch: 1-4 = 1 Round, 1-6 = 2 Round

This winding design makes the motor more reliable, especially for high performance and long-lasting use.

Understand the important terms

- SWG (Standard Wire Gauge): Indicates the thickness of the wire. The higher the number, the thinner the wire.

- Turns: The number of rounds of the wire coil.

- Coil Size: Wire coil banane ka total length.

- Coil Pitch: Coil is rounds is beech in distance.

- Capacitor: Helps in starting and running the motor.

FAQs (Frequently Asked Questions)

Q1: What is the difference between aluminum and copper wire?

A1: Copper wire provides more conductivity and durability, aluminium wire is lighter and cheaper.

Q2: How does the value of capacitor affect motor performance?

A2: Capacitor controls the starting and running torque of the motor. Wrong capacitor can damage the motor.

Q3: What is the meaning of coil pitch?

A3: Coil pitch is the distance between the turns of the coil, which affects the efficiency of the motor.

PDF Download

For your convenience, we have also created a PDF version of this complete Farata fan and exhaust fan motor coil winding data. You can download it from the link given below and refer it offline:

Click Here: Download Farata & Exhaust Fan Motor Coil Winding Data PDF

Conclusion

Understanding the Farata fan and exhaust fan motor winding data is very important for motor repair and manufacturing. The winding specifications of both aluminum and copper wire should be followed carefully so that the motor performance remains best. With the detailed data given above, you can easily do your motor winding work.

Don’t forget to give your feedback!

If you need more specific data or have any doubts about the winding, you can ask me!

If this article was helpful for you then please share it!

1 thought on “Farrata Fan & Exhaust Fan Coil Winding Data – 13 PDF Download”

सर नमस्कार, सर मेरा नाम एहसान है और मै देहरादून मै रहता हूँ सर क्या आप मुझे सभी तरहा के पंखे जैसे कूलर फर्रटा सिलिंग फैन का डाटा pdf भेज सकते है प्लीज, 🙏