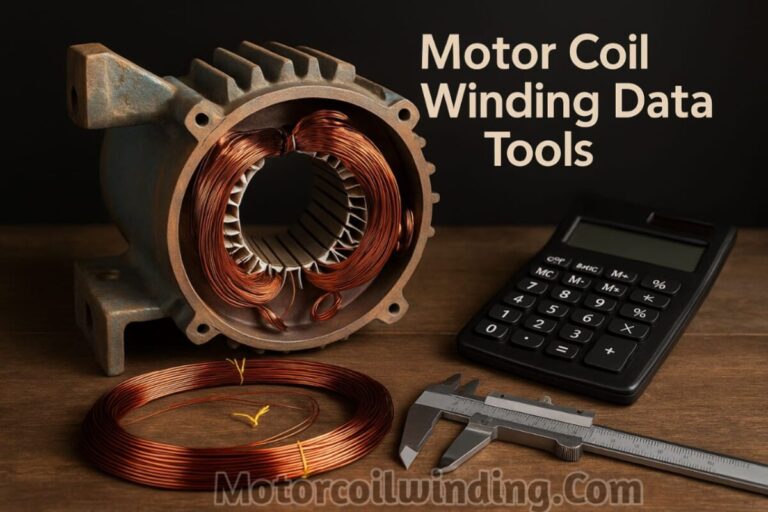

What is a motor coil winding machine, its types, price, and how to use it? Get all the important information, FAQs, and expert tips in this detailed guide

Motor Coil Winding Machine: How It Works, Types, Price, and Complete Guide.

What is motor coil winding machine?

Have you ever wondered how the copper wire winding inside electric motors, fans, or transformers is so perfect? Behind that perfection is a Motor Coil Winding Machine.

This is a machine that winds insulated wire in a specific pattern around a core or bobbin to form an electromagnetic coil. This improves the efficiency, durability, and performance of the motor.

How does a motor coil winding machine work? (working principle)

Its working is simple, but the process is very precise.

- Step-by-Step Process:

- Fixing the core/bobbin: Firstly, the core on which winding is to be done is fixed on the spindle of the machine.

- Setting up the wire: Copper or aluminum wire is wound off the spool and through the wire guide.

- Setting the turns: Sets the required number of turns on the machine (in automatic machines).

- Winding Start: As soon as the machine is started the wire starts to wind around the core.

- Uniformity Check: Traverse mechanism distributes the wire evenly.

- Completion: Machine stops when required turns are completed.

- Wire Cut & Remove: Wire is cut and coil is taken out.

Have you ever tried winding yourself? What difference did you feel between manual winding and machine winding?

Types of Motor Coil Winding Machine.

1.Manual Coil Winding Machine

- Best for small workshops or repair shops.

- Operated by a hand crank.

- Inexpensive, but speed and accuracy limited.

2.Semi-Automatic Coil Winding Machine

- Somewhat manual, somewhat automatic.

- Features like instant counter, speed control.

- For small to medium scale production.

3. Fully Automatic Coil Winding Machine

- Everything automatic: wire feeding, winding, cutting.

- High speed, high accuracy.

- For large scale industries.

4. CNC Coil Winding Machine

- Computer controlled,programmable.

- Complex winding patterns possible.

- For high-end motors, R&D labs.

Which machine do you think is best for your business/workshop?

Write your opinion below!

Key Features & Components.

| Part/Feature | Description |

|---|---|

| Spindle/Chuck | Where the core or bobbin is fixed. |

| Wire Guide | Guides the wire to the correct place. |

| Turns Counter | Counts the number of turns. |

| Traverse Mechanism | Winds the wire evenly. |

| Tensioner | Maintains tension of the wire. |

| Control Panel | For setting speed, direction, turns. |

Do you think that winding quality is improved due to torque counter and tensioner?

- Give us your feedback!

Where is the motor coil winding machine located?

- Transformers: Power & distribution transformers.

- Inductors & Chokes: Electronics industry.

- Relays & Solenoids: Automation systems.

- Automotive Motors: Cars, bikes, EVs

Which industry has the highest demand for winding machines in your area?

Let us know by commenting!

How to choose the best winding machine?

- Production Volume: How much quantity do I want to make?

- Coil Size & Type: Which size/type of coil do I want to wind?

- Budget: How much can I invest?

- Features: Turns counter, programmable settings, safety.

- After-Sales Support: Is service and parts available or not?

- Brand Reputation: Buy from trusted manufacturer only.

What is the most important feature for you – speed, accuracy, or price?

Write your answer below!

Price and Costing in India

Motor Coil Winding Machine Price Range (India)

| Type | Price Range (INR) | Typical Use |

|---|---|---|

| Manual | ₹1,000 – ₹14,000 | Small batches, prototyping, repair work |

| Semi-Automatic | ₹30,000 – ₹1,00,000 | Medium production, better consistency |

| Fully Automatic | ₹1,50,000 – ₹10,00,000+ | High-volume, industrial production |

| CNC Winding | ₹5,00,000 and above | Complex coils, high precision, automation |

This format engages people and buyers remember that not just price, quality, warranty and after-sales service are also important. If you want, you can make the post more interactive, like:

- Which machine do you want – manual, semi-automatic, fully automatic or CNC?

- Which brand of machine have you used? Share your experience in the comments!

Maintenance & Safety Tips

- Always keep the machine clean.

- Lubricate the moving parts.

- Keep checking the wire tension.

- Calibrate the turns counter.

- Seek the use of the emergency stop button.

- Wear gloves and safety gear.

Have a unique maintenance tip? Share it with other readers!

FAQs (Frequently Asked Questions)

Q1. Can quality winding be done using manual winding machine?

Ans: Yes, but speed and accuracy are less. Automatic machine is better for large scale.

Q2. Is winding machine used only for copper wire?

Ans: No, it can be used for aluminium or any conductive wire.

Q3. Is it easy for beginners to operate winding machine?

Ans: After basic training, it is quite easy to operate semi-automatic or automatic machines.

Q4. Is servicing of winding machine costly?

Ans: Regular maintenance keeps the servicing cost low. Major repairs may cost a little.

Q5. Can winding machine be bought online?

Ans: Yes, you can order from IndiaMART, TradeIndia, or directly from manufacturer’s website.

Conclusion & Your Experience

Today we learned in detail what Motor Coil Winding Machine is, how it works, its types, features, price, and what it is.